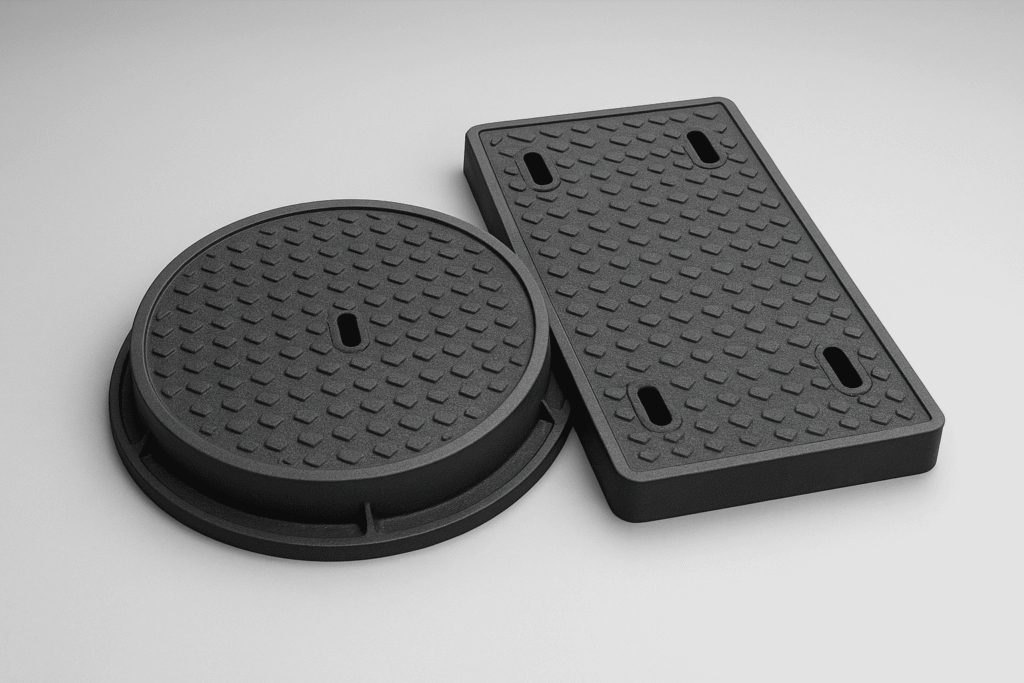

FRP Manhole Covers

Positioning: Lightweight yet high‑strength composite covers engineered for safety, security, and longevity.

What sets STERA apart

Fiber‑reinforced polymer matrix: High tensile strength with excellent fatigue resistance and zero scrap value (anti‑theft).

Weather & corrosion immunity: No rusting, rotting, or swelling in rain, chemicals, or salt air.

Non‑sparking, non‑conductive: Safer around electrical installations and fuel zones.

Anti‑skid textures: Molded surface patterns for wet‑grip safety.

Precision seating: Rattle‑free fit with gasket options for odour control.

Build quality & checks

Load class validation per typical municipal/industrial requirements (e.g., light duty to heavy traffic use cases).

UV‑ageing and temperature‑cycle tests; drop and impact resistance checks.

Dimensional tolerances verified for frame‑cover alignment.

Options & finishes

Square, rectangular, and circular covers; bolt‑down or hinged.

Custom branding and serial embossing available.

Customer benefits

High strength‑to‑weight ratio for easier handling and lower logistics costs.

Long service life without corrosion maintenance.

Safer in sensitive zones due to non‑conductive, non‑sparking properties.

Suggested visuals

Street‑level photo of textured FRP cover with embossed STERA logo.

Cross‑section diagram showing composite layers and ribbing.